Welcome back!

It takes me approximately 30 minutes to bind the top or back of a guitar. I always try to set myself up very well in advance since we are working against the clock here with glue that wants to jell.

For binding with wood bindings I use good old Titebond original. Others use other glues and this is fine so long as you get good results with what you use and are comfortable working with it.

Titebond can be a bit messy so I keep a large supply of paper towels ready to be used. I also try to be sure that I am using a bottle of Titebond that is not more then a year old. Titebond does come with a date code on it.

Additionally I always transfer some Titebond into a Wood Craft glue bottle simply because the applicator tip on the Wood Craft bottle is smaller and easier for me to control.

Here we see my set up - the bindings and purfs have been cut to size, the center of the tail end of the guitar is marked, tape and paper towels are in easy reach, and all is well.

Not shown is a cheap artist's brush that I use to help get the glue where I want it.

I start with spreading some glue from the center of the tail end of the guitar about half way up the lower bout. This distance is a distance that I can cover with the tape and bindings in several minutes. The glue is spread into the channel(s) and excess glue is wiped off.

It is very important to have your purfings and binding line up well with the mark that we made on the lower bout. This will ensure that the waist area of the bent bindings and purfings will fit well.

I also spread some glue on the side of the purfings that will contact the bindings.

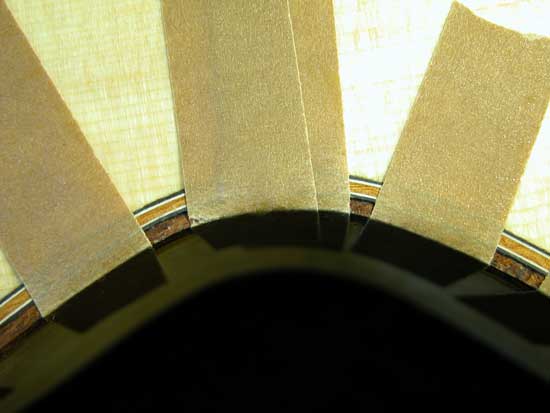

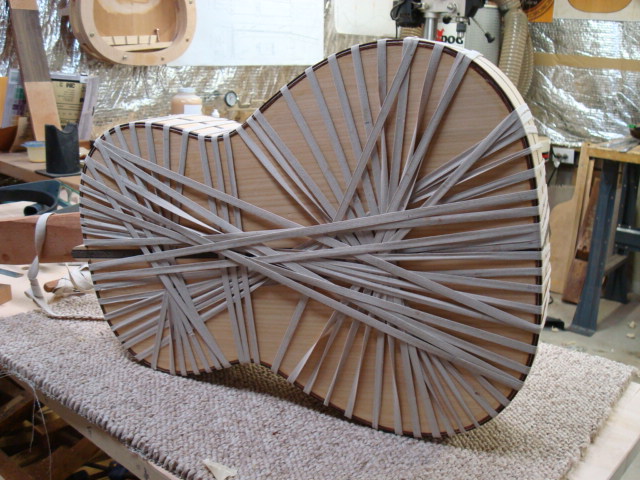

Once the bindings are aligned with the center mark I begin to tape them in place again starting at the center of the tail of the guitar. When using the brown tape I tape it to the side of the guitar first and then pull up and over as tightly as I can without breaking the tape or punching my hands through the top........ What we are looking to do here is pull the bindings and purfings as tightly as we can into the cut channels.

I always say that if my hands don't hurt when I am done binding a guitar then I didn't pull the tape tight enough.......

This process of buttering up the channels ahead of your progress is repeated as you work your way around the guitar. I make a point to go back to the starting point fairly quickly and then clean away the squeeze out from the channels where the bindings and purfings terminate. This makes getting a tight fit on the second half of the guitar much easier where the bindings and purfings will butt together.

Again the process is repeated and something that once started cannot be stopped. This is why all of a sudden you will see the completed guitar below.....

As soon as I have completed a side I closely check my work for any gaps and either adjust the tape or add more tape to close any gaps. Pay particular attention to the waist area in as much as this area is notorious for being gap prone. Also inspect the side of the guitar to be sure that the binding were seated all the way in the channels.

And of course the same process is repeated for the second half of the top of the guitar and then the back of the guitar.

I typically will wait at least 4 hours before removing the tape and at least 24 hours before scraping the bindings level. When working with plastic bindings and a solvent based glue it is even more important to wait at least 24 hours before scraping the bindings because the solvent based glue will shrink as the solvents dissipate into the air. Once the .....shrinkage..... is complete your results with scraping level will be better.

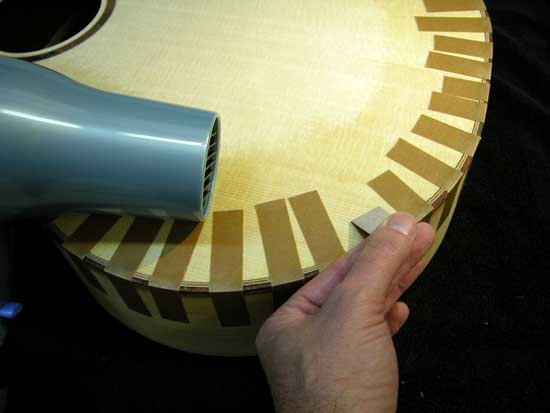

To remove the tape I gently warm the tape with a hair dryer and this helps to release the adhesive. In addition I am always sure to pull the tape in a direction that is in the neighborhood of 45 degrees to the grain and from the center of the guitar toward the edges. This will also help avoid any tear out or lifting of top fibers.

For me the key to a good binding job is fitting everything very well in advance and being set up so that once you start everything that you need is close at hand.

Thanks folks and happy binding!

We argue about this issue often here on the OLF and at the risk of being redundant, or overly redundant.....

We argue about this issue often here on the OLF and at the risk of being redundant, or overly redundant.....

tape. the ends of the 20 yards or so of material are fastened by tapping in aluminum push pins in an area that is solid and won't be seen once the guitar is finished. The tape is then removed by sliding the cloth binding aside and peeling as you describe, this provides for quicker drying of the glue and a fit check.

tape. the ends of the 20 yards or so of material are fastened by tapping in aluminum push pins in an area that is solid and won't be seen once the guitar is finished. The tape is then removed by sliding the cloth binding aside and peeling as you describe, this provides for quicker drying of the glue and a fit check.